Embarking on an industrial floor restoration project can seem like a daunting task. However, with the right knowledge and preparation, these endeavors can significantly enhance the longevity and functionality of your industrial space. This guide will offer essential advice for planning and executing an effective industrial floor restoration, covering everything from choosing the right materials to hiring skilled professionals, and ensuring your project runs smoothly and successfully.

Getting The Right Tools

The first step in any successful industrial floor restoration project is acquiring the right tools and equipment. From concrete grinders to epoxy applicators, having access to high-quality tools will ensure that your project runs efficiently and produces professional results. It’s essential to research which tools are necessary for your specific flooring type and consult with professionals if needed. The folks at https://www.niagaramachine.com/ note that there are many machines and equipment available online, making it easy to find what you need for your project. It’s also crucial to invest in high-quality tools that will last and provide consistent results.

Understanding Your Flooring Needs

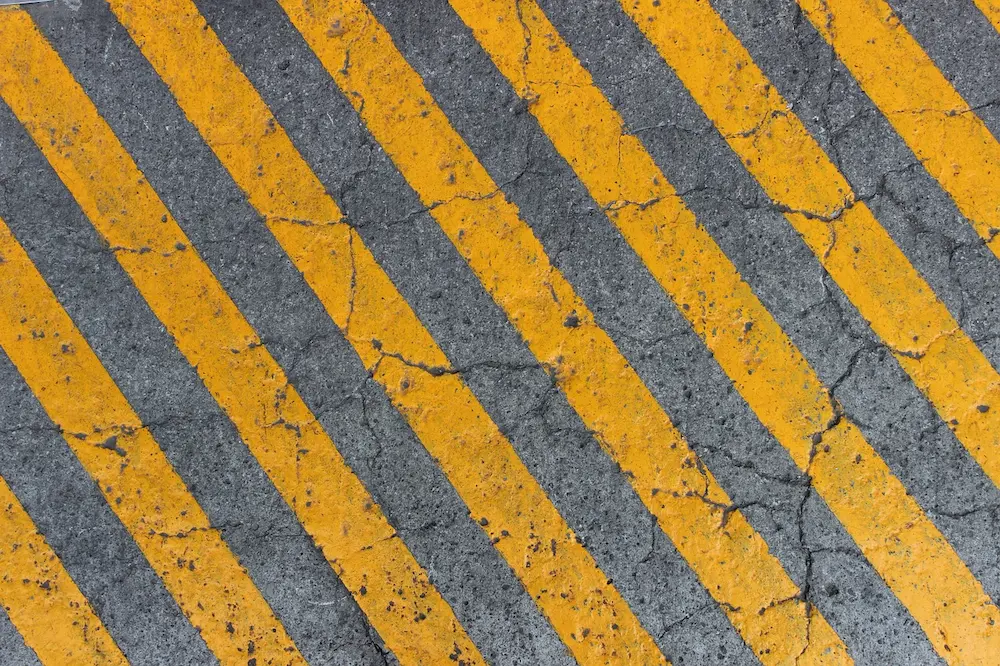

Identifying your unique flooring needs is the first step in any industrial floor restoration project. Consider the nature of your operations, the volume of foot and machine traffic your floor will endure, and any specific environmental factors such as exposure to chemicals or high temperatures.

In addition, think about the desired longevity of your new floor. Investing in high-quality materials and professional installation can offer longer-term benefits, despite the initial cost.

Finally, include safety considerations in your decision-making process. Certain materials offer more slip resistance than others, which may be crucial in a busy industrial environment.

Choosing the Right Materials

Materials play a key role in industrial floor restoration. Each material has its own set of benefits and potential drawbacks, and understanding these will help you make an informed decision.

For instance, epoxy resin flooring is known for its durability and resistance to chemicals, making it a popular choice for many industrial settings. However, it may crack under continuous heavy impact.

Concrete, on the other hand, is extremely robust and resistant to heavy loads but may require additional treatments to increase its resistance to chemical spills and high temperatures.

Hiring Skilled Professionals

Hiring skilled professionals for your floor restoration project can help ensure a successful outcome. These experts can offer valuable advice on material selection, installation methods, and maintenance protocols.

Furthermore, a professional team can efficiently handle any unexpected issues that arise during the project, minimizing delays and keeping the project on track.

Remember, the cheapest quote may not always be the best option. Consider the experience, reputation, and customer testimonials when choosing your contractor.

Preparing for the Restoration Process

The preparation phase is critical in any floor restoration project. This includes clearing the area of machinery and other obstacles, cleaning the existing floor, and making any necessary repairs to the sub-floor.

Additionally, consider how the restoration process will impact your operations. You may need to adjust your production schedule or temporarily relocate certain activities to accommodate the work.

Communicating these alterations clearly to your team will help ensure a smooth transition and minimize disruption to your workflow.

Caring for Your New Floor

Post-restoration, it’s essential to establish a regular maintenance schedule to prolong the life of your new floor. This could involve regular cleaning to remove debris, periodic sealing or painting to maintain its appearance, and prompt repair of any damage.

Educate your team on the correct care procedures for your new floor. This will help prevent unnecessary damage and ensure everyone contributes to maintaining the floor’s condition.

Remember, proper care and maintenance is an investment in the longevity and functionality of your industrial floor.

Evaluating the Success of Your Project

After completion, take the time to evaluate the success of your floor restoration project. Consider whether the new floor meets your needs in terms of durability, safety, and functionality.

If there were any issues during the project, think about what could have been done differently to avoid them. This reflection can provide valuable insights for future projects.

Finally, collect feedback from your team. Their firsthand experience with the new floor can provide useful information about its performance and any potential improvements.

In conclusion, with proper planning, the right tools and materials, skilled professionals, and diligent maintenance, an industrial floor restoration project can greatly benefit your business. Use this guide as a starting point to ensure a successful and long-lasting outcome for your next flooring endeavor. With the right resources and approach, you can transform your industrial space into a safe, durable, and efficient working environment. By implementing these essential pieces of advice, you will set your project up for success and achieve a high-quality restoration that meets your specific needs. Let this be the first step towards improving the functionality and longevity of your industrial space.